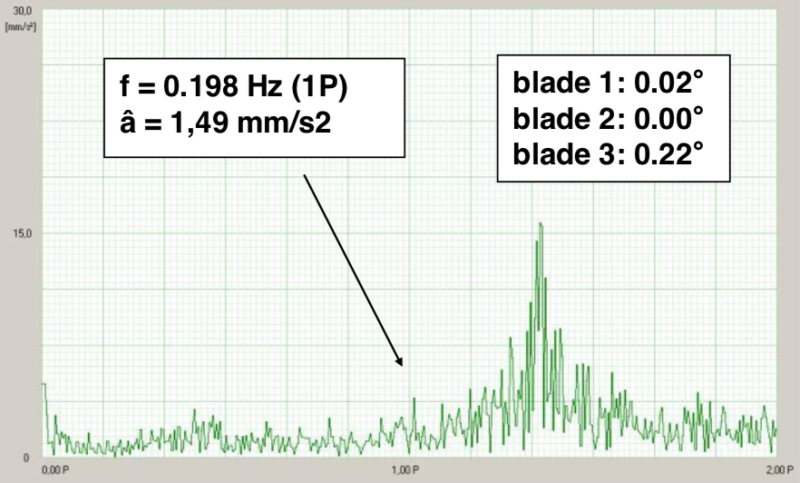

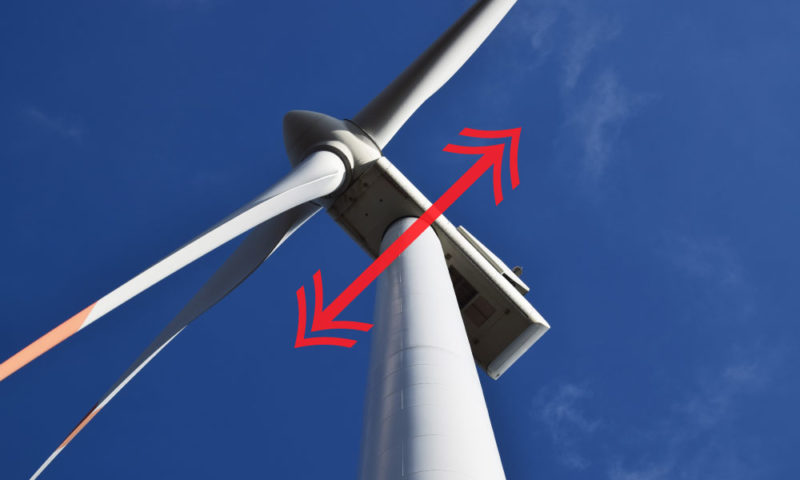

Aerodynamic imbalance

Axial vibrations due to aerodynamic imbalance can lead to premature failure of fatigue critical components (main frame, gearbox,…) which needs to be avoided.

Unpredicted vibrations can cause a shorter life-time of your wind turbine. Keep the targeted life-time-value via an inspection regarding vibrations and make corrections before large damages are occurring.

Case 1:

Axial vibrations due to aerodynamic imbalance

Case 2:

Radial vibrations due to mass imbalance

Case 3:

A combination of both

Axial vibrations due to aerodynamic imbalance can lead to premature failure of fatigue critical components (main frame, gearbox,…) which needs to be avoided.

All blades set to nominal

Using high precision sensors, the blades are individually set to minimize the vibrations.

Axial vibrations due to mass imbalance can lead to premature failure of fatigue critical components (main frame, gearbox,…) which needs to be avoided and performance loss due to increased cut-in wind speed.

Performing measurements, determination of correction masses and placement.

Lead weights around the blade root (smaller turbines)

Water filled inflatable bags (larger turbines)

Placement of correction masses on spar web

A combination of aerodynamic imbalance and mass imbalance causes axial and radial vibrations. This leads to a solution combining the best technologies eliminating axial and radial vibrations.